has anyone ever built or seen a 5-9hp surface drive motor? I think it would be the bee's-knee's on my otter stealth.

small hp surface drive

1 reading

mailyard

21 - 40 of 200 Posts

The motor is ungoverned and running around 4600-4800 rpms. The gear ratio was calculated using the pitch diameter of the pulleys and should be close to 1.5. The speed was measured with a gps and could be a little off, but the motor pushed the thing scary fast considering the final attack is an 8 foot plastic boat. I've been working on another motor but am having trouble with it eating through belts I'll try to post some pictures later.

Joined

·

35 Posts

ok, that makes more sense to me.The motor is ungoverned and running around 4600-4800 rpms.

do you think ill be able to pull 3600rpm with a 1-1 ratio, 5" pitch prop and 7hp?

please post pictures of your new setup. why is it eating belts?

im a machinist, maybe we can trade resources.

this sight; http://www.speedymetals.com/default.asp ... 5Qodo0wlrw has some standard size tubing. pipe is different.

I've thinking of doing something like this. What about running chain and sproket, instead of a belt drive? pros? cons?

Richard

Richard

Joined

·

35 Posts

that was my origanal idea. guy at work talked me out of it. a belt my be a little more forgiving if you hit something. scavenger uses belts. my engine has a one inch diameter shaft and i had a hard time finding two gears with the same pitch and diameter with different bores(1" and 3/4"). i would have prefered to use timming pulleys since they wont slip even if they get wet. i used v-belt pulleys. you can use automotive belts with them.I've thinking of doing something like this. What about running chain and sproket, instead of a belt drive? pros? cons?

I think you will need more torque to spin a 9x5 inch prop. I tried around a 1.1-1 ratio for my first test run and only got up to 5 mph. I Also tried running a tiger 10x8 surface drive prop at 1.5-1 and it staled the motor as soon as the prop hit the water. Mcmaster-Carr sells variable pitch pulleys that will let you play around with different gear ratios without buying a lot of pulleys http://www.mcmaster.com/#.do you think ill be able to pull 3600rpm with a 1-1 ratio, 5" pitch prop and 7hp?

Joined

·

65 Posts

don't wanna kill this awesome homeade surface drive thread but mud buddy makes a 9hp surface drive

Finished motor set up to run on 3 gallon fuel tank.

![Image]()

Dog, motor, and a mixed bag limit.

![Image]()

Motor on Carsten Canvasback. Had to get a bigger boat to handle the extra weight. The final attack looked like it was gonna sink with a full load and the motor.

![Image]()

Probably the biggest change from the prototype to this finished motor is the box. Instead of trying to weld up a 6x4 in steel box I bought a 22in section of 6x4in aluminum rectangular tube with 1/8in wall from Discount Steel http://www.onlinemetalstore.com/items/6063_Aluminum_Rectangular_Tube.cfm. The whole set up weighs around 85-90 lbs (I don,t have a good scale to weigh it with). When the boat is fully loaded it will just barley get up on plane and do around 11-12 mph at 4100-4200rpm's with 1.5to1 reduction ratio. Still working some of the bugs out so hopefully I will be able to squeeze a little more power out of the engine when I have things fine tuned.

Dog, motor, and a mixed bag limit.

Motor on Carsten Canvasback. Had to get a bigger boat to handle the extra weight. The final attack looked like it was gonna sink with a full load and the motor.

Probably the biggest change from the prototype to this finished motor is the box. Instead of trying to weld up a 6x4 in steel box I bought a 22in section of 6x4in aluminum rectangular tube with 1/8in wall from Discount Steel http://www.onlinemetalstore.com/items/6063_Aluminum_Rectangular_Tube.cfm. The whole set up weighs around 85-90 lbs (I don,t have a good scale to weigh it with). When the boat is fully loaded it will just barley get up on plane and do around 11-12 mph at 4100-4200rpm's with 1.5to1 reduction ratio. Still working some of the bugs out so hopefully I will be able to squeeze a little more power out of the engine when I have things fine tuned.

Joined

·

1,855 Posts

I've followed this thread for awhile, congrats on you work. :thumbsup: Just out of curiousity, where are you located? The background in those pics look similar to the backgrounds in our ND pics...regardless it makes me miss ND already.

Brad

Brad

Very nice upgrade. That motor looks great on your new boat! :thumbsup:

Did you have to do anything special to switch over to the 3gal tank? Does the motor pull the fuel in on it's own?

Erich

Did you have to do anything special to switch over to the 3gal tank? Does the motor pull the fuel in on it's own?

Erich

Joined

·

35 Posts

that looks great!

i had planned on doing something simular but using 4-1/2" x 1-3/4" aluminum channel. i have 3.55" diameter pulleys. how did you seal the ends of the box? i was thinking about having mine tig welded. also, do you think the bearing mounted in the box is nessecary? i was thinking about using locking collars on my shaft with flange bushings to control the thrust of the prop.

great job!

i had planned on doing something simular but using 4-1/2" x 1-3/4" aluminum channel. i have 3.55" diameter pulleys. how did you seal the ends of the box? i was thinking about having mine tig welded. also, do you think the bearing mounted in the box is nessecary? i was thinking about using locking collars on my shaft with flange bushings to control the thrust of the prop.

great job!

Joined

·

35 Posts

well, i pulled the trigger and ordered some material to start buildind mine. i got a 2 foot length of 5 x 3 x 1/8" aluminum rectangle tubing, a matching cover, 2 ft of 1-1/2" .5" wall aluminum tubing, two 3" lengths of 2" .5 wall tubing, a 36" 3/4" 303 stainless shaft, 2ft of 7/8" .065" steel tubing for handle, 5 x 8 x 1/8" plate and 2 x 2 square tubing for my motor mount.

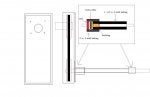

i attached a crude drawing(i have a better one with dimentions drawn on deltacad if anyones interested) of the box and shaft setup. comments and crtique apreciated. thanks in advance.---tom

i attached a crude drawing(i have a better one with dimentions drawn on deltacad if anyones interested) of the box and shaft setup. comments and crtique apreciated. thanks in advance.---tom

Attachments

-

37 KB Views: 6,921

Joined

·

35 Posts

Joined

·

35 Posts

Joined

·

42 Posts

Just wondering if anybody has one of these motors or longtail or outboard on a stealth boat, and not on the factory motor mount for the stealth boat. If so how did you attatch to the boat if so can you please attatch a pic to. I starting to build a surface drive for one thanks Also one more ? is what size of pulleys did run on this motor if you dont mind me asking

Joined

·

35 Posts

anybody seen this? 18 mph with 5hp and 3900 rpm. i gotta se if i can get one of those props.

The copperhead just hit the internet last week. It's a nice looking motor from what I can see. They're still working on the website and getting more info out there. I too am interested in thier prop. :thumbsup:

Erich

Erich

I,m actually located in Northern CaliforniaJust out of curiousity, where are you located? The background in those pics look similar to the backgrounds in our ND pics

That copperhead motor is pretty impressive. I wonder which Hopkins propeller there running or of its a special prop they don't have listed under there Louisiana Mud Buster Props? Anyways here is a link to Hopkins mud buster props http://www.hopkinspropeller.com/mudprops/

Tom I,m Glad to see that you decided to take the plunge and start building. I like your design with the bushing it simple and cheap i just wonder how long the one on the prop end will last with the lock collar pushing against it all the time, but building these motors is definitely a process of trial and error. Did you go with the .5in wall tubing so the locking collar would fit in the 2" tube cause that is really thick tubing. another question I had was how are you planning the keep the seals in place.

Erich the motor won't pull it own fuel so I used a Walbro fuel pump. The GX 200 engine is used by kart racers so the are tons of aftermarket parts, like the top plate that mounts where the fuel tank used to be, the fuel pump is mounted on that plate.

00buckhunting check out this link to Utah marsh motors for a pic of a longtail mounted to a stealth http://www.utahmarshmotors.com/Utah_Marsh_Motors_-_Feature.php. The outside diameter of the pulley on the motor is 3.55in and the driveshaft pulley is 5.15in they are from Mcmaster-Carr.

Thanks for the clarificaiton on the fuel pump! :thumbsup:Smallboat said:I,m actually located in Northern CaliforniaJust out of curiousity, where are you located? The background in those pics look similar to the backgrounds in our ND pics

That copperhead motor is pretty impressive. I wonder which Hopkins propeller there running or of its a special prop they don't have listed under there Louisiana Mud Buster Props? Anyways here is a link to Hopkins mud buster props http://www.hopkinspropeller.com/mudprops/

Tom I,m Glad to see that you decided to take the plunge and start building. I like your design with the bushing it simple and cheap i just wonder how long the one on the prop end will last with the lock collar pushing against it all the time, but building these motors is definitely a process of trial and error. Did you go with the .5in wall tubing so the locking collar would fit in the 2" tube cause that is really thick tubing. another question I had was how are you planning the keep the seals in place.

Erich the motor won't pull it own fuel so I used a Walbro fuel pump. The GX 200 engine is used by kart racers so the are tons of aftermarket parts, like the top plate that mounts where the fuel tank used to be, the fuel pump is mounted on that plate.

00buckhunting check out this link to Utah marsh motors for a pic of a longtail mounted to a stealth http://www.utahmarshmotors.com/Utah_Marsh_Motors_-_Feature.php. The outside diameter of the pulley on the motor is 3.55in and the driveshaft pulley is 5.15in they are from Mcmaster-Carr.

I also agree with you that 0.5in wall tube is really thick and not needed for strength requirements. I'd save the weight and go with a thinner wall and pay to have some minor machining done instead. :wink:

Erich

Joined

·

35 Posts

im using flange bushings to handle the thrust. they have a 1-1/4" face. the tubing i have is aluminum. sizes were picked for cleanence of the collars and to fit the seals i will be using.

i found some 3/4" id x 1-1/2"od seals for a briggs and stratton pto shaft on ebay. they should be easy to find if i have to replace them and i figured these would be heavy duty and can be tapped into place with a mallat since the outside is brass and made to do so.

one of the 2" diameter peices will be welded to the front cover and braced. the 1-1/2" tube will mount inside that with set screws.

i will post some pictures after my camera batteries are charged.

i found some 3/4" id x 1-1/2"od seals for a briggs and stratton pto shaft on ebay. they should be easy to find if i have to replace them and i figured these would be heavy duty and can be tapped into place with a mallat since the outside is brass and made to do so.

one of the 2" diameter peices will be welded to the front cover and braced. the 1-1/2" tube will mount inside that with set screws.

i will post some pictures after my camera batteries are charged.

Attachments

-

31.6 KB Views: 6,263

Joined

·

35 Posts

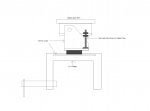

shaft assembly and upper motor mount.

Attachments

-

136.4 KB Views: 6,288

-

87 KB Views: 6,264

-

104.3 KB Views: 6,231

-

96.4 KB Views: 6,262

21 - 40 of 200 Posts

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 3.2M

- members

- 65K

- Since

- 2000

A forum community dedicated to duck hunters and hunting enthusiasts. Come join the discussion about safety, gear, tips, tricks, optics, hunting, gunsmithing, reviews, reports, accessories, classifieds, and more!